Johnson Space Center

For more than half a century, NASA’s Lyndon B. Johnson Space Center in Houston has led our nation and the world on a continuing adventure of human exploration, discovery and achievement. The center has played a vital role in powering our country into the 21st century through technological innovations and scientific discoveries.

Location

Houston, Texas

Founded

November 1, 1961

People

11,000+

Director

Vanessa Wyche

Giant Leaps Start Here

Whether you represent industry, government, academia, or the general public, step inside and explore the opportunities, capabilities, technology and data available to you. We invite you to connect with us as we embark to expand frontiers in exploration, science, technology, and the space economy.

Step Inside about Giant Leaps Start Here

Johnson Leadership

Vanessa E. Wyche, Director

Vanessa E. Wyche is the director of NASA’s Johnson Space Center, home to America’s astronaut corps, Mission Control Center, International Space Station, Orion and Gateway programs and its more than 11,000 civil service and contractor employees.

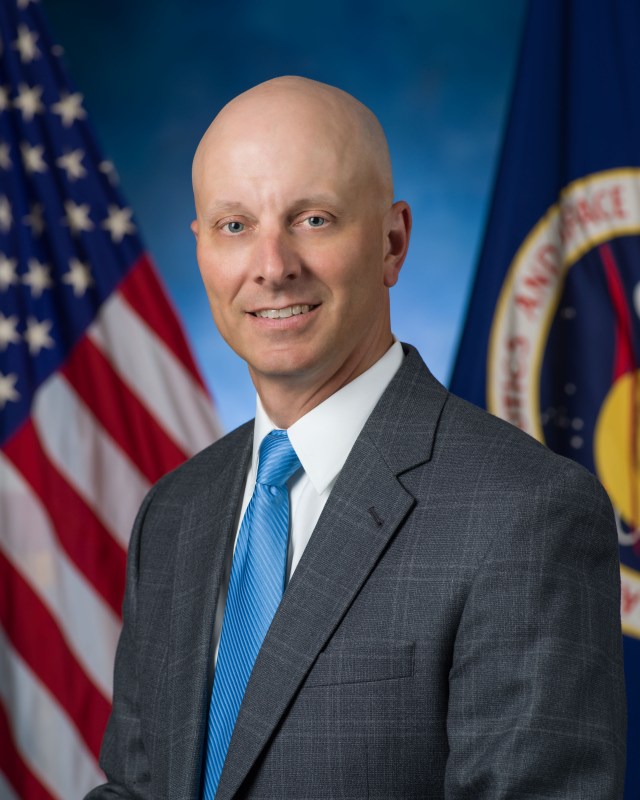

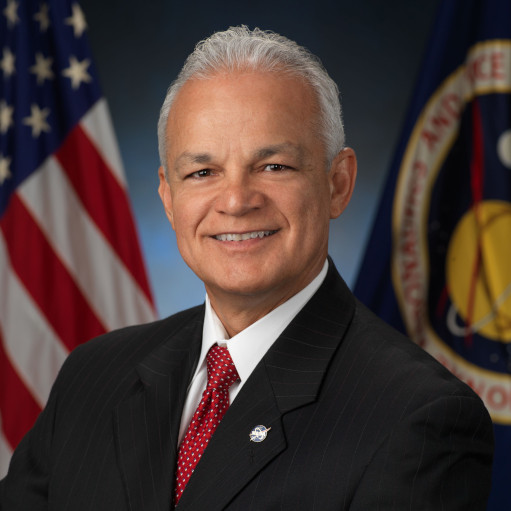

Stephen A. Koerner, Deputy Director

Stephen A. Koerner assists in overseeing a broad range of human spaceflight activities, including development and operation of human spacecraft, commercialization of low-Earth orbit and Johnson’s role in landing the first woman and first person of color on the surface of the Moon.

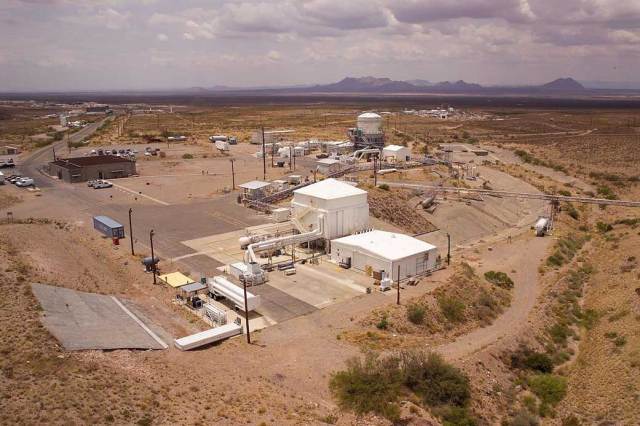

Donna M. Shafer, Associate Center Director

Donna M. Shafer assists in leading a workforce of more than 10,000 civil servant and contractor employees at one of NASA’s largest installations in Houston and the White Sands Test Facility in Las Cruces, New Mexico. She also assists with a broad range of human spaceflight activities.

Douglas Terrier, Associate Director for Vision and Strategy

Douglas Terrier is responsible for leading the strategy, creation, integration, and overall execution of JSC’s ongoing transformation initiatives revolutionizing the center’s policies, plans, and processes around workforce, facilities, and products to advance human spaceflight.

Jennifer Scott Williams, Assistant to the Center Director for Technical Integration

Jennifer Scott Williams is the Assistant to the Center Director for Technical Integration. She began her NASA career in 2001 working as a Space Shuttle flight controller in the Instrumentation and Communications Group. She went on to work in the Minority University Research and Education Program, the International Space Station Program.

Luis G. Ramirez, Technical Assistant to Deputy Center Director

Luis G. Ramirez is the Technical Assistant to Deputy Center Director. Luis became part of the NASA family through the JSC Cooperative Student Education program. He served as a Shuttle flight controller, was certified as an Artemis I flight controller and an Artemis II team lead. In April of 2020, Luis accepted a position within the Orion Program Office as a systems engineer and integration lead.

Focus Areas and Capabilities

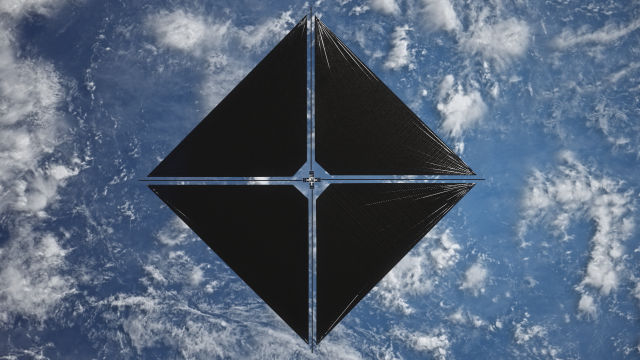

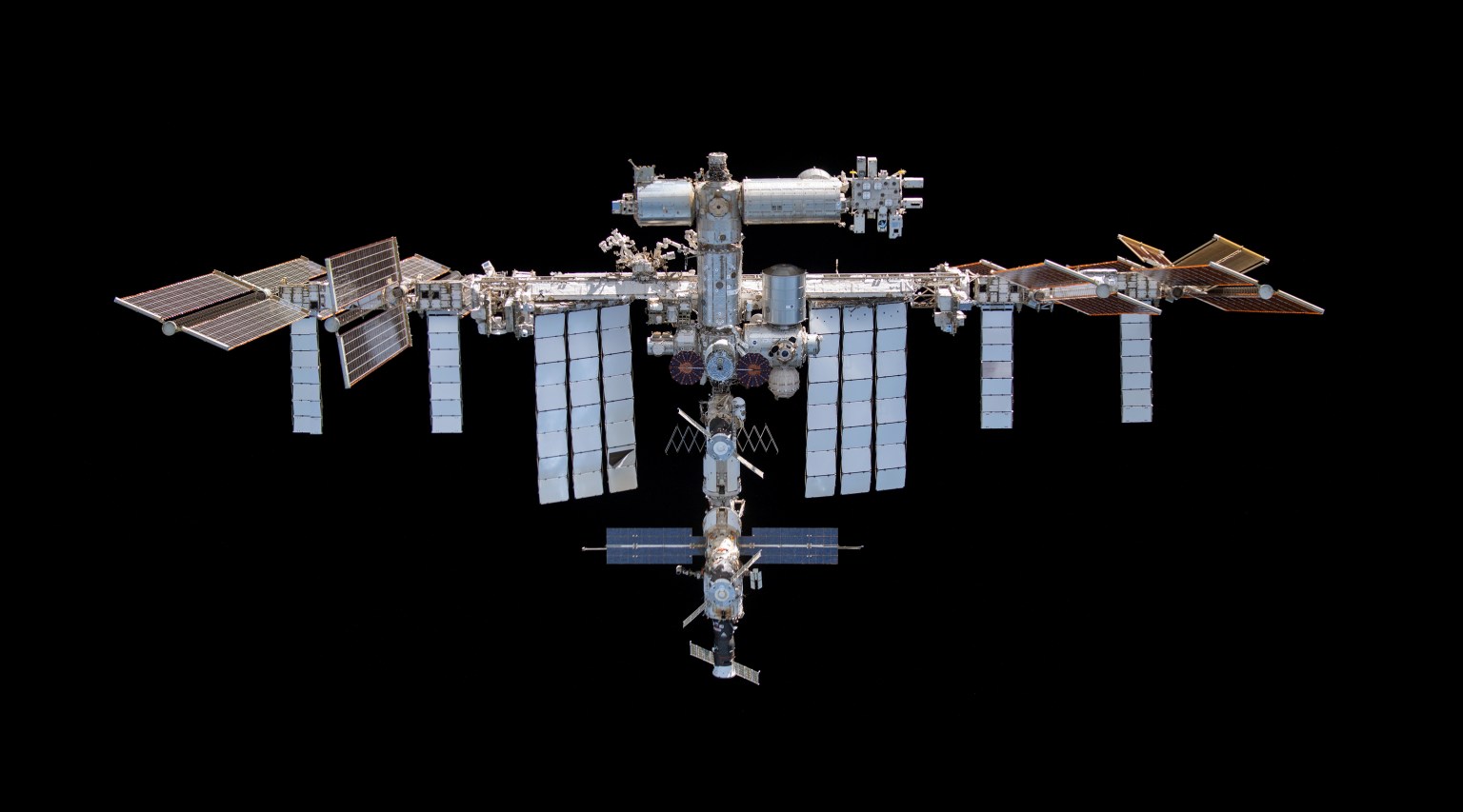

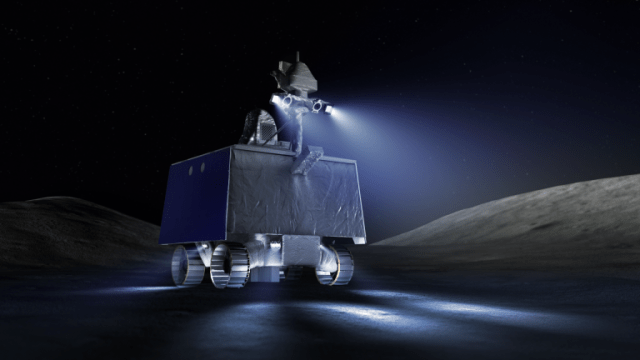

Humans in Space

Human space exploration helps to address fundamental questions about our place in the universe and the history of our solar system. We go to space to answer humanity's most fundamental questions, to create new economic opportunities, and to improve life on Earth.

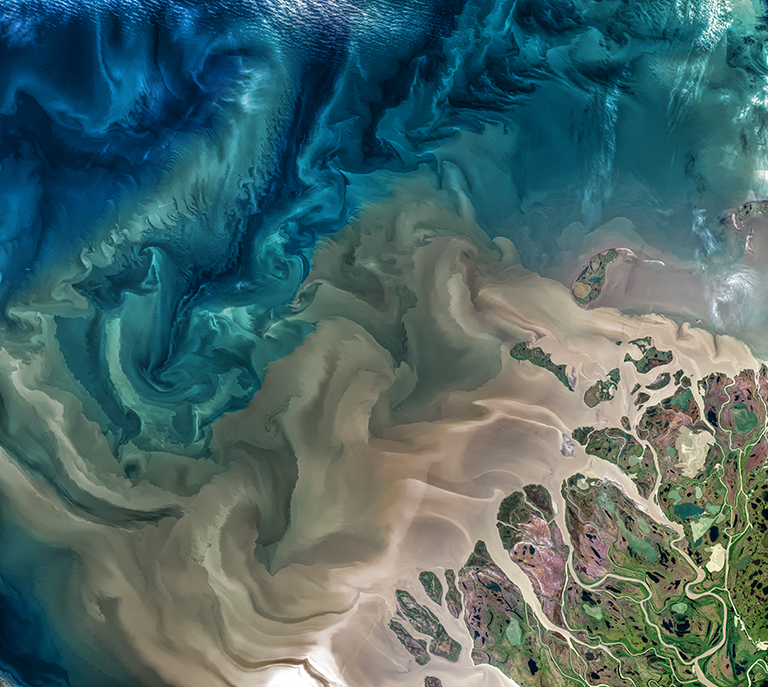

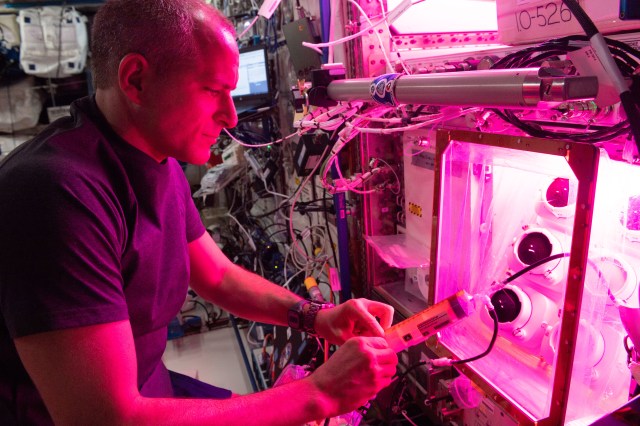

Research

Johnson Space Center research efforts span biology and biotechnology, Earth science, human research, physical science, technology, and more.

Commercial Space

The first foray into economic development off Earth, the low-Earth orbit economy is a new and growing market of private companies providing access to, and services in, space. Customers in space include NASA and other international space agencies, academic institutions, and other research-based organizations.

Labs and Facilities

Explore NASA Johnson's labs and facilities to learn more about their capabilities.

Food Laboratory

The Space Food Systems Laboratory supports the production and development of flight food, menus, packaging, and food-related hardware for all NASA programs.

Lunar Sample Laboratory

Geologic samples returned from the Moon by the Apollo lunar surface exploration missions (1969-1972), along with associated data records, are physically protected, environmentally preserved, and scientifically processed in a special building dedicated for that purpose.

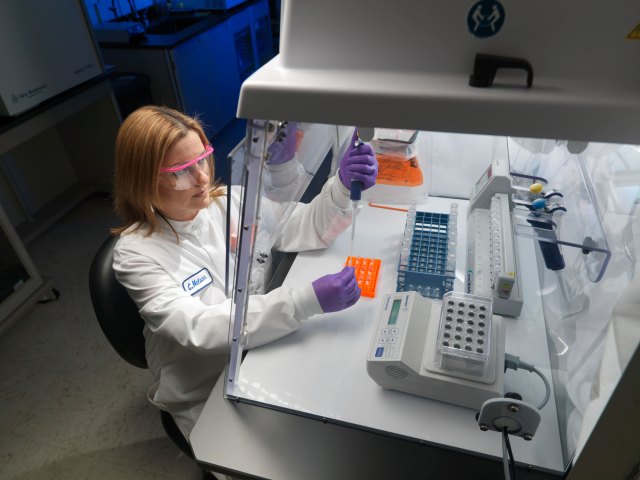

Microbiology Lab

The Johnson Space Center Microbiology laboratory, a Biosafety Level 2 facility, is a critical component of the Human Health and Performance Directorate and is responsible for addressing crew health and environmental issues related to microbial infection, allergens, and contamination.

Mission Control Center

The mission operations team enables the men and women living and working aboard the space station to achieve their mission goals and to fly safely. The next generation of mission operations will include deep space travel beyond Low Earth Orbit, into Cislunar space, and onto Mars.

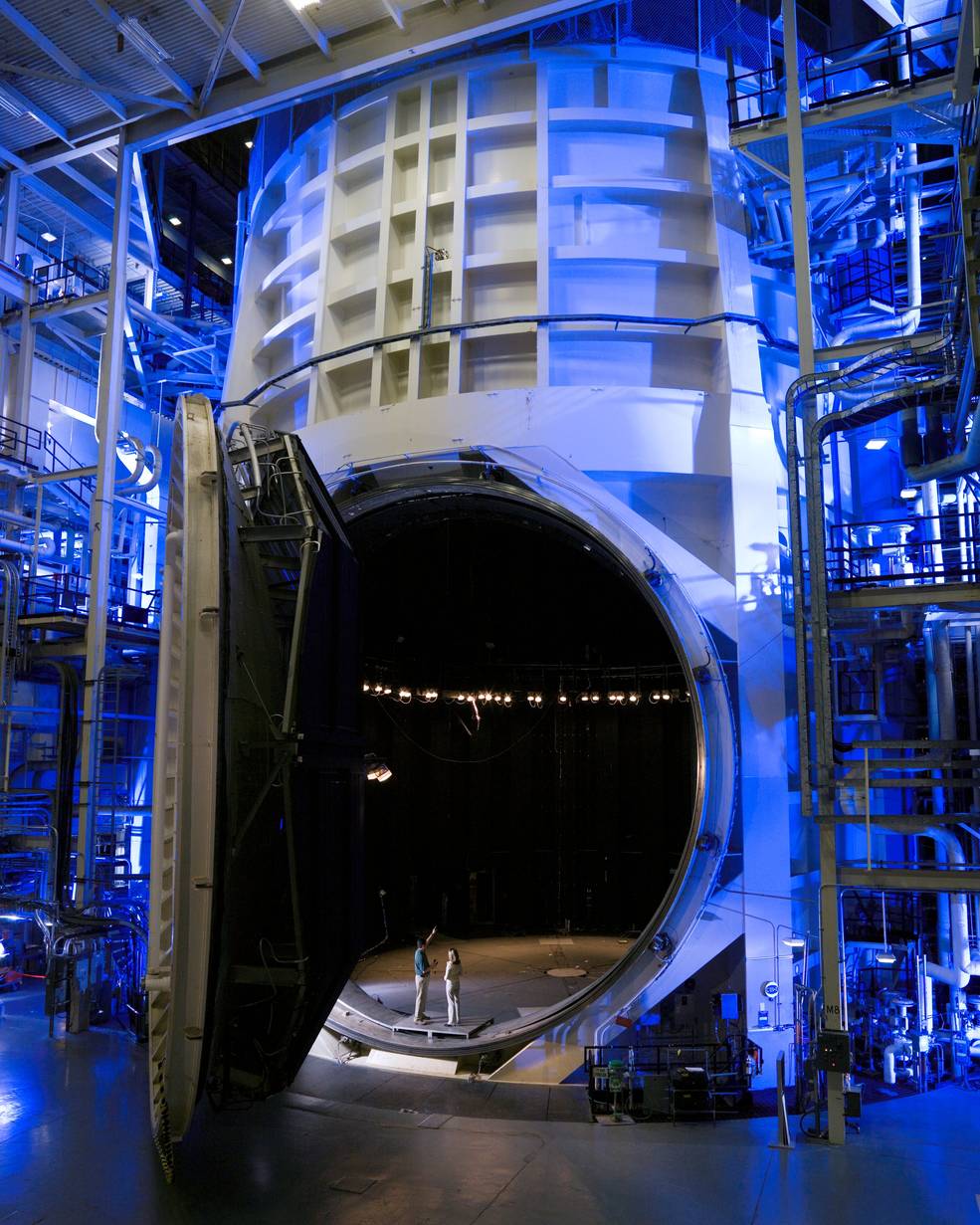

Neutral Buoyancy Laboratory

The NBL is one of the world’s largest indoor pools and can support multiple large scale operations utilizing both underwater and topside assets simultaneously. The NBL is utilized for mission planning, procedure development, hardware verification, astronaut training, and refinement of time-critical operations necessary to ensure mission success during spacewalks.

Space Vehicle Mockup Facility

The mission of the SVMF is to provide world class training for space flight crews and their support personnel and high-fidelity hardware for real-time mission support. A major task of the SVMF is to support engineering and mission operations evaluations for the International Space Station and Orion Programs.

NASA TV – The place to be.

Johnson Space Center Image Gallery

More NASA Centers

Explore NASA Centers.